Vaccum dewatering system

Model : SVF-900EF

Dia : 900mm

Dish/Blade thickness : 6mm/3mm

Weight : 100 kg

- Vaccum dewatering system gives higher Compressive strength and faster initial setup, so reduce economical cost.

- The system done fast construction work so reduce labour work cost.

- The system gives most economic and suitable for heavy duty floors, therefore reduce maintenance cost

- 28 days strength gained in 7 days so save curring time.

- Reduse shrinkage and permeability so give high compressive strength.

- Vaccum dewatering system control water resio so benifit in concrete strength.

- Vacuum dewatering system flooring gives batter finishing so help to improve quality of work.

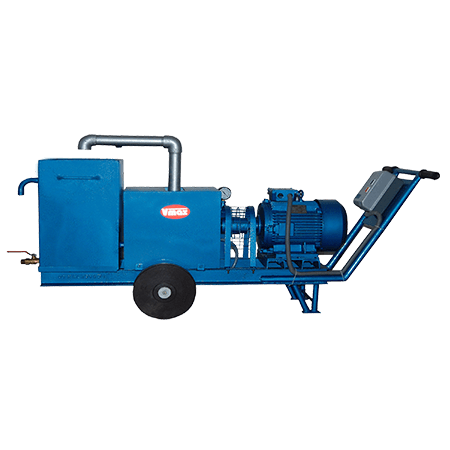

Shree Vinayak Industries Manufacturer of Vaccum dewatering system . The system used mainly concrete flooring. The vacuum dewatering System basically improves strength, durability, and

other properties of concrete by reducing the water cement ratio immediately after the mix is placed, usually in floors and other flatwork. It provides better wearing and tearing property. The system include sce

ed vibrator, vdf pump and power trowel machine. The system used in highway concrete road, industrial floor , runways, container yards, etc

After concrete laying and screeding, the concrete was immediately covered with a filter pad and a suction mat connected to a vacuum pump. Within seconds the vacuum created under the mat began to compress the concrete and cause water to be drawn through hoses to the suction pump.

Features :

Specification :

| Model | Working Area | Top mat size | Bottom net size | Weight(full system) | Power unit | |

| SVD-1E | 7.600 Sq. Mtr | 4000 mm* 2200 mm | 3800 mm *2000 mm | 225 Kg | 7.5 HP, 3Ph Electrical motor |

Reviews

There are no reviews yet.